Can You Use A Tire Repair Kit In Cold Weather

Fewer Repairs But More Critical

Tire repairs have been a basic component of a tire dealer's business organization e'er since the beginning of the tire industry. Car owners could count on making a tire repair on nearly every drive they took in the 1890s considering tires weren't sophisticated. In those days, the repairs were fabricated past the car owner, for the most part.

Click Here to Read More

Today, "flats" are nigh a thing of the by. Manufacturers make tires that are technologically advertisingvanced and can withstand about road hazards. The appearance of the radial tire, a much sturdier design than the old bias ply tire, reduced the need for repairs and supplied more than miles per tire. But these higher tech tires do receive injuries from road hazards such as nails, bolts and other sharp metallic objects.

Because of their more sophisticated structure, however, when today'southward tires are damaged and must be repaired, the repair can't be done by the boilerplate driver. It tin can and should exist done by a tire service technician who has been trained to practice a complete, proper repair.

This article includes sequential photos that show the accepted industry standards of how a tire should be repaired. The repair procedures are for rider and light truck tires, but are virtually the same for medium truck tires (except for Step 17, every bit noted). The photos also concentrate on a standard two-slice repair, with 1 photo showing a one-piece process – substantially the same as a 2-piece with the 1 exception.

Getting Started

We recommend that all tires be properly repaired per guidelines past both the RMAand TIA, and demonstrated here. Repairs should be express to puncture injuries of not more than ¼-inch (6mm). Don't brand repairs where the injury damage extends into the shoulder/belt border area or where the injury extends at an bending into the shoulder area. If the injury does extend into the shoulder/belt edge, fleck the tire.

Proper tools and repair materials must be used; we have included a list of the basic tools in this article.

Improperly repaired tires can fail while in service, including tread-chugalug separations and/or detachments. These occurrences may cause an accident resulting in serious personal injury or death.

Call up that not all tires can be repaired. Specific repair limits should be based on recommendations or the repair policy of the tire manufacturer and/or type of tire service – service description, run-flat technology or commercial service applications, for example.

For all tires, repair units tin can't overlap. The number of repairs should exist limited commencement past the tire manufacturer's recommendations and repair policy, then by the application and the tire's condition as determined by the inspection process.

Some run-apartment technology tires tin can't be repaired. Technicians should consult tire manufacturers for their repair policies and, if applicative, for their recommended repair procedures.

Industry recommended repair methods include:

1. 2-piece plug and patch repair components.

2. 1-piece patch/stem combination repair units.

For punctures angled greater than 25 degrees, RMA recommends two-piece plug and patch repair components.

Never Means Never

An onetime phrase states, "Never say never," but "never" is alright when repairing tires, according to RMA.

• Never repair tires with a tread puncture larger than ¼-inch (6mm).

• Never repair tires worn to the tire'southward treadwear indicators or to 2/32-inch remaining tread depth in any area of the tread.

• Never perform a tire repair without removing the tire from the rim/cycle assembly and completing an internal inspection. Do not perform an outside-in tire repair or on-the-wheel repair; these types of products are non considered full, permanent repairs and should be residuumricted to temporary use only. It is essential that only a particularly-trained person remove any tire from the wheel when it has been damaged or is losing air. A thorough inspection for whatsoever internal damage can and so be made.

• Never utilize only a plug (stem) and never use only a patch to repair a puncture. The injury must be completely filled with a suitable vulcanizing material or a safe plug/stem and a patch must exist applied to the innerliner to prevent air loss.

• Never repair a tire that has an existing, improper (non-RMA) repair. The tire must exist scrapped.

• Never substitute an inner tube for a proper repair or to remedy an improper repair.

• Never invert radial tires – and avoid excessive spreading of the tire or tire beads.

• Never vitrify the innerliner as well deep, exposing the tire casing body (ply) cords. If this type of damage occurs during buffing, the tire must be scrapped.

For Safety'due south Sake

Technicians should be aware of a few warnings communicated by RMA. As pointed out, tires must always be properly repaired as shown in the accompanying department with sequential photos. If improperly repaired, tires may neglect in service.

When repairing a tire, acceptable middle protection (goggles or face shields) should always be worn to prevent serious centre injuries. Ear protection should also be worn.

Permanent tire damage due to underinflation and/or overloading can't always be detected. Ply cords damaged past underinflation or overloading may break and cause a "attachment" in the upper sidewall with instantaneous air loss and explosive force. These damaged tires should be inflated only when using a restraining device or prophylactic cage that complies with OSHA regulations and an air line with a clip-on air chuck.

Products from dissimilar repair fabric manufacturers should not be mixed.

Step-by-Footstep Tire Puncture Repair Procedures

The following "how to" photos and captions show and explain accepted manufacture procedures for repairing tire puncture injuries. Additional information is available on RMA's website – rma.org – and by requesting its Puncture Repair Procedures information, or by requesting data about TIA's Basic Automotive Tire Service training series, which includes a module dedicated to puncture repair.

ane. Consult information about repairability of tires.

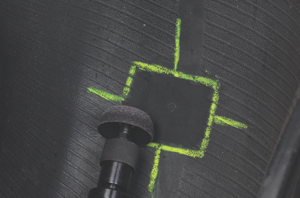

2. Locate the injury and circumvolve with a tire crayon. DO NOT INVERT RADIAL TIRES.

3. Remove the strange puncturing object and probe the injury with an awl to decide the bending of penetration.

4. Clean the surface area around the injury with cleaner fluid and a scraper.

5. Using a low speed drill (max. 500-700 rpm) and a 3/16-inch tapered carbide cutter, ream the injury following the bending of penetration from the inside of the tire. Use proper eye protection.

6. Remove the poly from the plug stem. Hook the stalk into the wire puller. Glaze the unabridged plug with self-vulcanizing cement. Notation: With jumpsuit repair units the patch section must exist coated, too.

seven. While the cement is even so wet, push the wire puller through the injury from the inside of the tire. Grasping the wire, employ a steady pull until ½-inch of the gray safety on the plug is exposed exterior the tire.

7a. FOR ONE-Slice REPAIRS: While the cement is all the same wet, insert the guide wire through the injury from the within. Using pliers, grasp the stem behind the wire and pull until the patch is seated against the innerliner. Practise not over-pull and cause the patch to dimple.

8. Using a flexible knife, cut the plug on the within of the tire 1/8-inch above the innerliner. Be careful not to stretch the plug when cutting.

9. Making sure the dewdrop arrows of the repair unit are pointing to the chaplet, center the proper size repair unit over the injury. Use a tire crayon and outline an expanse ½-inch larger than the repair unit.

ten. Utilize a low-speed buffer (max. 5,000 rpm) and a buffing rasp to vitrify the plug and the outlined innerliner area. BE CAREFUL NOT TO Buff THROUGH THE INNERLINER.

11. Employ a vacuum to completely remove the buffing dust.

12. Use a light glaze of cleaner fluid to the buffed area, scrape clean and allow to dry.

13. Utilize an fifty-fifty glaze of self-vulcanizing cement to the unabridged buffed area. Let cement to dry out until tacky. Never apply blow dryers, compressed air or heat lamps to facilitate drying. Drying fourth dimension is affected by temperature and humidity.

14. When cement is dry, partially remove the poly backing from the repair unit, leaving but enough to agree the unit of measurement. Press the unit of measurement into place while removing the residual of the backing.

15. Sew the repair unit vigorously from the heart working outwardly. Use as much hand pressure level every bit possible. Remove peak encompass picture show.

16. Employ repair sealer on the overbuff area, and over the edge of the repair unit.

17. Apply bead sealer to the dewdrop of the tire before inflation to help prevent air loss around the bead. (NOT NECESSARYFORTRUCK TIRES.)

18. After inflating, cut the plug stalk flush with the outside tread area. The tire is now ready to exist returned to service.

Click on these links to download a full poster version of this illustrated two-piece tire puncture repair guide, as well as i that details single-piece tire puncture repair procedures.

After downloading, take the PDF file to a local role supply store (OfficeMax, Staples)or FedEx Kinkos location, where y'all can print out a full-color, 18×24-inch affiche to hang in your tire service surface area and/or customer waiting surface area.

List of Basic Repair Tools:

Awl

White paintstick (truck tire)

Tire Crayon

Scraper

Safety Glasses/Shield

Depression-Speed Buffer/Skiver

3/16-inch Carbide Cutter

3/16-inch Adapter

5/xvi-inch Adapter (truck tire)

Pulling Wires

Knife

Black Contour Cup – 60 Grit

Adapter with Spacer

Stitcher

When Not to Repair a Tire

• There is 2/32-inch or less of tread on any 2 adjacent tread grooves. The tire is non legal on U.Due south. highways.

• The tire cord or steel belt is exposed, at that place are flex breaks or severe sidewall abrasions.

• There is whatever evidence of a separation in the tread area or the sidewall of the tire.

• There is whatever evidence to indicate the tire has been run apartment. Practise not inflate, since aggrandizement could result in serious injury. Demount the tire and audit for innerliner impairment.

• At that place are punctures or damage in the shoulder or sidewall areas.

• Never use any bicycle with a rim that is aptitude, pitted from corrosion, cracked or worn. Remove rust, dirt and foreign materials from cycle/rim parts.

When 'Always' is right

• Inflate the tire to maximum allowed pressure. Exercise not overinflate.

• Check the surface and the valve for the source of the leak(south) by using water, soap solution or leak detector.

• Locate the injury and circle with a crayon.

• Remove the valve core to debunk the tire.

• Demount and audit the inside of the tire on a well-lighted spreader for innerliner cracks, open splices, exposed tire cord or steel belts, cleaved beads or bead wires, bulges or blisters, or other interior damage. If any damage other than a ¼-inch maximum puncture injury in the tread is present, practice not repair.

Final Inspection

The final inspection is your last chance to make sure a tire puncture repair task was done properly and within industry standards. A proper repair must completely fill up the injury with a suitable vulcanizing material or rubber plug/stem and a patch must be practical to the innerliner to forestall air loss.

Inspect all of your repairs and rework, if necessary. After removing and inflating the tire/wheel associates, inspect the assembly (tire/wheel/valve) for impairment or leakage. Pay particular attending to the location of the repair, the chaplet and the valve. If the tire continues to lose air, it must be removed again from the wheel for a consummate re-inspection.

Radial Department Repair

The procedures for repairing a more serious injury on a radial medium truck tire are notably different than when repairing a minor puncture. Department repairs may require special tools and repair materials, including strip glue rubber, an extruder, a spot curing press, particularly designed repair units and more than.

The procedure described here is very basic; special training is required to properly perform section repairs.

While the steps for probing an injury bending and buffing are the aforementioned, a grinding (skiving)step must be added to remove all damaged wires and the length and width of the damaged area must exist measured to assist in selecting the proper repair unit.

For crown repairs, skives should be a cupped "Y" type with a 90-degree skive through the wire belts and ply. Stitching should be done as in a regular repair prior to curing the repair and allowing it to absurd.

Next, a cleaner fluid should exist applied and the innerliner should exist scraped clean. When placing the repair unit over the injury, center it with the bead arrows pointing directly to the chaplet. Using a tire crayon, outline an area one-inch larger than the repair unit of measurement.

Perform the buffing step, vacuum the grit and apply a lite coat of rubber cleaner fluid and a scraper to clean the buffed area. Apply an fifty-fifty glaze of cocky-vulcanizing cement to the entire buffed surface area and allow to dry until tacky.

Make sure the tire is in a relaxed position. Partially remove the backing from the repair unit, leaving enough to hold without touching the dorsum. Apply the patch and press downward.And so sew the unit, working out from the middle. Use as much paw pressure as possible. Every bit a final footstep, use repair sealer to the over buff area and over the edges of the repair unit.

Disclaimer

Repairing a tire is serious business. The preceding article was researched and written using existing industry-approved procedures and material from both the RMA and TIA, and is NOTintended to be used every bit a substitute for proper tire repair grooming. The photos and additional information were supplied past Myers Tire Supply/Patch Safety Co. The process shown here is consistent with those used past other major repair product makers, simply consult their specific instructions earlier using. This data represents a consensus of tire industry experts. This commodity is meant for educational purposes and those who use the methods recommended are solely responsible for whatever injuries, deaths or losses resulting from their awarding.

Can You Use A Tire Repair Kit In Cold Weather,

Source: https://www.tirereview.com/back-to-basics-1-basic-tire-repair/

Posted by: colterpruch1964.blogspot.com

0 Response to "Can You Use A Tire Repair Kit In Cold Weather"

Post a Comment